-

Telekomünikasyon

-

Fiber Optik Kablolar

-

< div class="menu-icon">

Konvansiyonel Kablolar

Konvansiyonel Kablolar

-

< div class="menu-icon">

OPGW

OPGW

-

< div class="menu-icon">

ADSS

ADSS

-

< div class="menu-icon">

Denizaltı Kablolar

Denizaltı Kablolar

-

< div class="menu-icon">

WTC (Dünyada en Yüksek Fiber Kapasiteli Kablo)

WTC (Dünyada en Yüksek Fiber Kapasiteli Kablo)

-

< div class="menu-icon">

-

Optik Fiberler

-

< div class="menu-icon">

Multi Mode

Multi Mode

-

< div class="menu-icon">

Single Mode

Single Mode

-

< div class="menu-icon">

Özel Uygulamalar için Fiberler

Özel Uygulamalar için Fiberler

-

< div class="menu-icon">

-

Fiber Ek Cihazı ve İlgili Ürünler

-

< div class="menu-icon">

Telekomünikasyon Uygulamaları

Telekomünikasyon Uygulamaları

-

< div class="menu-icon">

Özel Uygulamalar

Özel Uygulamalar

-

< div class="menu-icon">

-

Optik Test Cihazları

-

< div class="menu-icon">

Optik Spektrum Analizörler

Optik Spektrum Analizörler

-

< div class="menu-icon">

OTDR

OTDR

-

< div class="menu-icon">

Optik Dalgaboyu Ölçüm Cihazı

Optik Dalgaboyu Ölçüm Cihazı

-

< div class="menu-icon">

Modüler Üretim Test Sistemi

Modüler Üretim Test Sistemi

-

< div class="menu-icon">

Taşınabilir Optik Güçölçerler & Işık Kaynakları

Taşınabilir Optik Güçölçerler & Işık Kaynakları

-

< div class="menu-icon">

Taşınabilir Ethernet Test Cihazları

Taşınabilir Ethernet Test Cihazları

-

< div class="menu-icon">

-

RF Ürünleri ve Telekom Kuleleri

-

< div class="menu-icon">

Konnektörler & Adaptörler

Konnektörler & Adaptörler

-

< div class="menu-icon">

Kablolar

Kablolar

-

< div class="menu-icon">

Test Cihazları

Test Cihazları

-

< div class="menu-icon">

Antenler

Antenler

-

< div class="menu-icon">

Saha Çözümleri

Saha Çözümleri

-

< div class="menu-icon">

Aletler ve Aksesuarlar

Aletler ve Aksesuarlar

-

< div class="menu-icon">

Telekom Kuleleri

Telekom Kuleleri

-

< div class="menu-icon">

-

Bakır Telekomünikasyon Kabloları

-

< div class="menu-icon">

Bakır Telekomünikasyon Kabloları

Bakır Telekomünikasyon Kabloları

-

< div class="menu-icon">

-

F/O Kablolar için Montaj Aksesuarları

-

< div class="menu-icon">

F/O Kablolar için Montaj Aksesuarları

F/O Kablolar için Montaj Aksesuarları

-

< div class="menu-icon">

-

El Aletleri

-

< div class="menu-icon">

Koaksiyel Kablolar için

Koaksiyel Kablolar için

-

< div class="menu-icon">

Fiber Optik Kablolar için

Fiber Optik Kablolar için

-

< div class="menu-icon">

Elektrik Kabloları için

Elektrik Kabloları için

-

< div class="menu-icon">

Güç Kabloları için

Güç Kabloları için

-

< div class="menu-icon">

-

Fiber Muayene ve Temizlik Ürünleri

-

< div class="menu-icon">

Fiber Muayene

Fiber Muayene

-

< div class="menu-icon">

Temizlik Kitleri

Temizlik Kitleri

-

< div class="menu-icon">

Basmalı Tip Temizleme Ürünleri

Basmalı Tip Temizleme Ürünleri

-

< div class="menu-icon">

Makaralı Tip Temizleme Ürünleri

Makaralı Tip Temizleme Ürünleri

-

< div class="menu-icon">

Fiber Optik Temizleme Sıvıları

Fiber Optik Temizleme Sıvıları

-

< div class="menu-icon">

Temizleme Mendilleri ve Temizleme Kartuşları

Temizleme Mendilleri ve Temizleme Kartuşları

-

< div class="menu-icon">

Temizleme Çubukları & Uçları

Temizleme Çubukları & Uçları

-

< div class="menu-icon">

-

Optik Aksesuarlar

-

< div class="menu-icon">

Merkez Ofis Uygulamaları

Merkez Ofis Uygulamaları

-

< div class="menu-icon">

Optik Kabinler

Optik Kabinler

-

< div class="menu-icon">

Çok Katlı Bina Çözümleri

Çok Katlı Bina Çözümleri

-

< div class="menu-icon">

Kutular ve Optik Prizler

Kutular ve Optik Prizler

-

< div class="menu-icon">

Optik Bölücüler

Optik Bölücüler

-

< div class="menu-icon">

Optik Ek Kutuları

Optik Ek Kutuları

-

< div class="menu-icon">

-

-

Enerji

-

Madencilik

_4f0de13d-6191-4f2b-8da7-4d4706281433.png)

- Medikalde Fiber

- Güneş Pili

Fiber Ek Cihazı ve İlgili Ürünler

Clad Alignment Fusion Splicer 41S+ Kit

Ürün Kodu YRLNYJ

The 41S+ is now equipped with "ACTIVE FUSION CONTROL TECHNOLOGY" and "ACTIVE BLADE MANAGEMENT TECHNOLOGY" to maintain consistent low loss splicing results. These two technologies, allow customers to achieve more stable low-loss splicing, reducing the need for rework and re-splicing.

Features

Active Fusion Control Technology

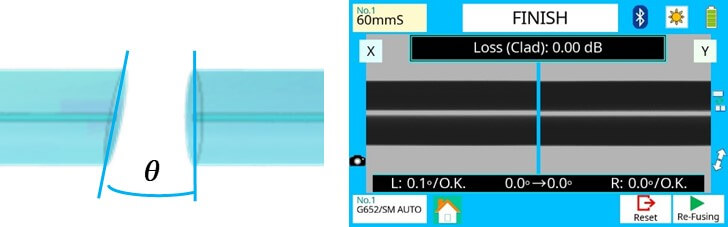

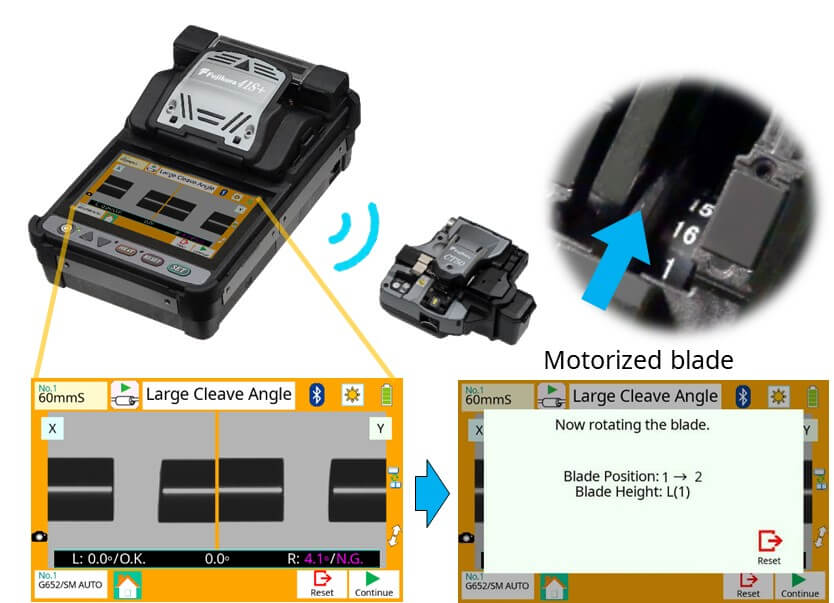

1. Active Fusion control by cleave condition

One of main causes of high splice loss is bad cleave end face quality. The 41S+ analyzes the condition of both L and R cleave end faces and applies optimal fusion control. This new technology improves splice loss significantly and greatly reduces needs for rework.

Splice loss with large cleave angle : 3 <θ< 5 degree

*G.652 splicing result measured with a cut-back method. The splicing result changes depending on the fiber type and fiber characteristics.

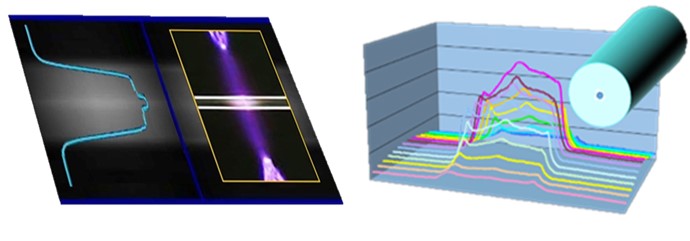

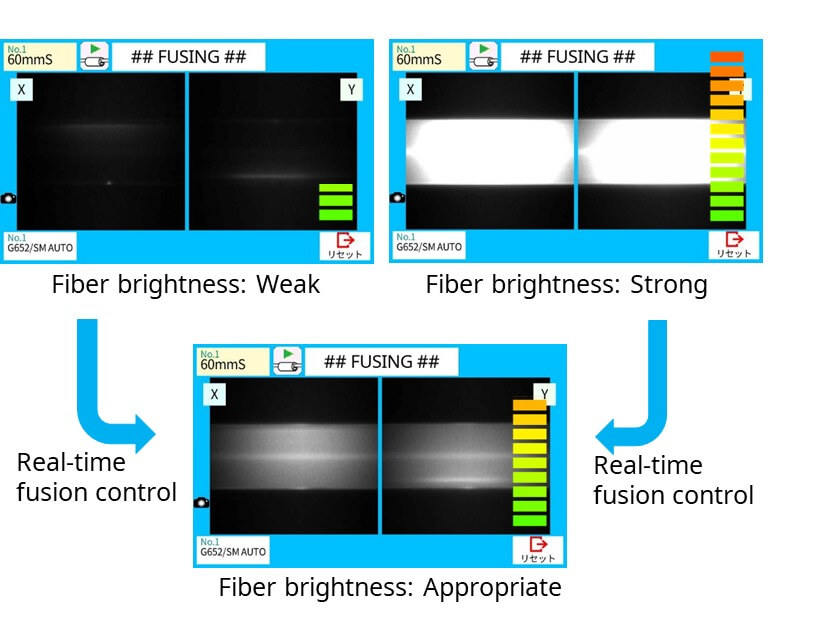

2. Active Fusion control by fiber brightness

Fusion is easily affected by changes in the environment.

The 41S+ uses real-time fusion parameter control by analyzing the fiber brightness intensity during splicing. This contributes to stable, low-loss splice results.

Analyzing the fiber’s brightness intensity

Active Blade Management Technology

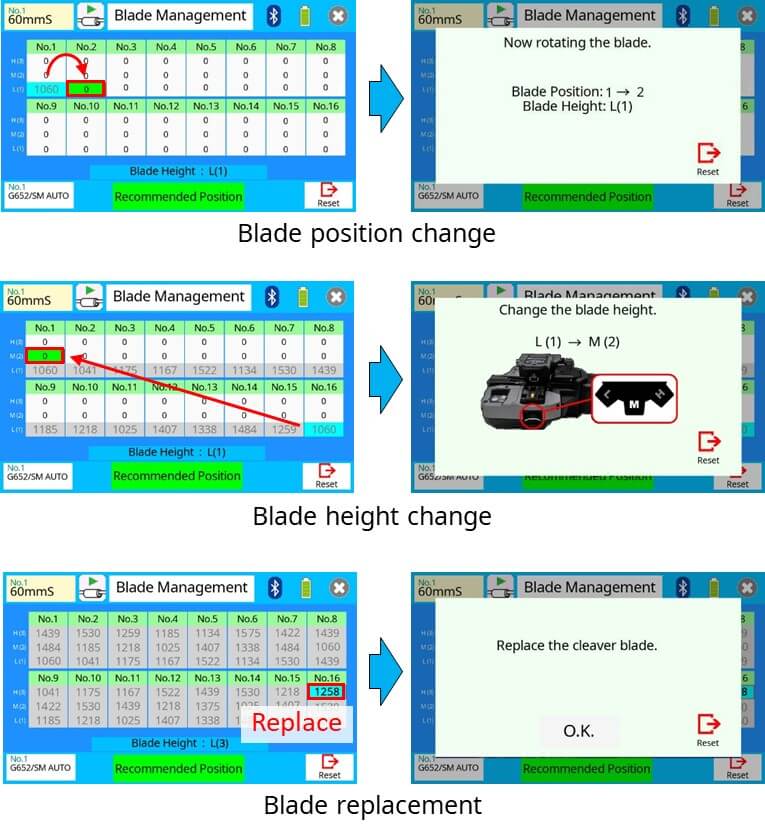

1. Active Blade rotation by motor

The 41S+ and CT50 fiber cleaver are equipped with wireless data connectivity. This capability allows automatic cleaver blade rotation when the 41S+ judges the blade is worn.

2. Active Blade life management

The 41S+ displays the remaining blade life and informs the user when a blade height change, blade position change, or new blade is required.

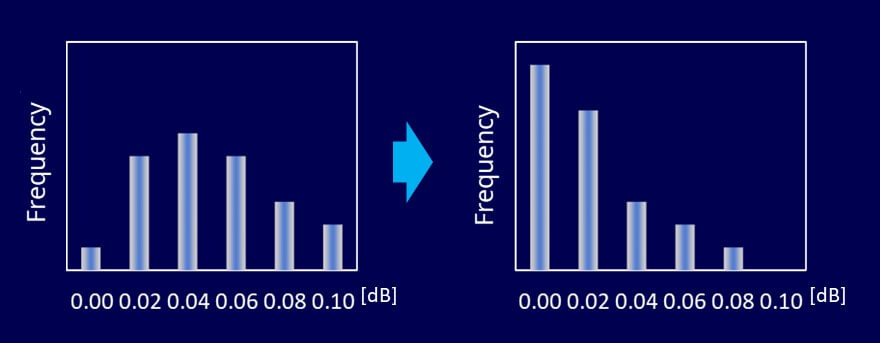

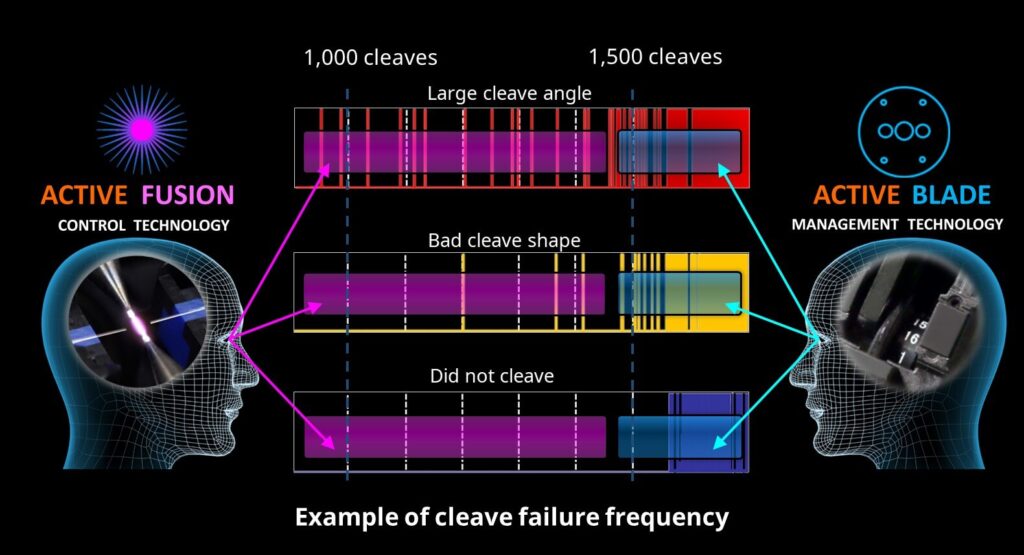

Enhanced Splice Quality

The graphs below show the number of cleaves on the horizontal line with frequency of large cleave angle, bad cleave shape and failure to cleave. When the frequency of large cleave angle or other cleave problems increases, Active Blade Management Technology can detect this increasing ratio of poor cleaves and rotate the blade position automatically. Active Blade Management Technology therefore significantly reduces the frequency of poor quality cleaves. Even when a poor cleave is detected, the 41S+ compensates by using Active Fusion Control Technology to apply optimized fusion to reduce the incidence of high splice loss.

By using these 2 key technologies together, the 41S+ minimizes the occurrence of high splice loss and greatly reduces the need for rework and re-splicing.

User Friendly

1. Easy Fiber Protection Sleeve Positioning

The shape of the sheath clamp is optimized for the 60mm length protection sleeve. The length from the splice point to the edge of the sheath clamp is 30mm. Therefore, it is easy to center the protection sleeve over the splice by using your finger as the reference point.

2. Universal Tube Heater

The 41S+ fusion splicer can accommodate splice sleeves with a diameter of up to 6.0mm. Therefore, it supports a wide range of protection sleeve sizes.

3. Easy replacement of consumable parts

3-1 Tool-less Electrodes replacement

The 41S+ electrodes comes as an assembly including electrode mounting fixture and thumb screw. The thumb screw is easily loosened or tightened by hand without tools. This enables easy electrode replacement.

Electrodes replacement without tools

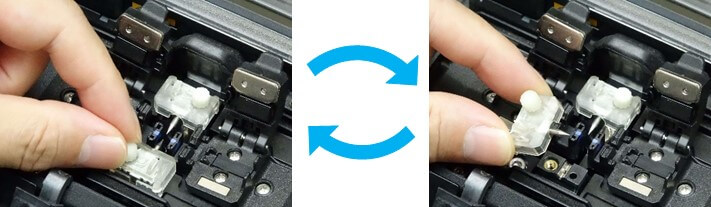

3-2 User replaceable blade and rubber clamps

The CT50 fiber cleaver has a user replaceable blade and rubber clamps – there’s no need to send the device to a service center for blade or clamp replacement.

Replaceable rubber clamps

Replaceable blade

4. Carrying Case

There are multiple ways to utilize the 41S+ carrying case. The 41S+ is ready to use just by opening the case, but the splicer with an included work tray can also be removed. The tray can be placed on top of the carrying case or other work surface, mounted it on a tripod, etc.

5. Work Tray

The work tray has a drawer which can slide open to expand the work area. The tray has convenient features such as a recess to lock an included alcohol dispensing bottle in place to prevent it from falling.

BENZER ÜRÜNLER

The 90R12 is a mass fusion splicer capable of splicing up to 12 fiber ribbon cables simultaneously. In previous mass fusion splicer models, the v-grooves could become dirty over time due to debris and glass deposits from splicing accumulating in the v-grooves. Which in turn, could lead to fibre offsets and high losses if they were not regularly cleaned which added to the overall process time. The 90R12 comes with a first of its kind, innovative user replaceable V-groove assembly which makes this issue a thing of the past and is supplied as standard equipment with the 90R12 kit. This new V-groove assembly can be quickly and easily fitted in the field, minimizing downtime and maximising productivity. In addition, the new V-groove design enables splicing of both conventional type 12-fiber encapsulated ribbon and SWR (Spider Web Ribbon) whilst also accommodating 250um and 200um pitch fibers. The 90R12 can also splice single fibers if required. also making use of Active Blade Management Technology, which now can connect to two CT50 cleavers simultaneously.

Ürün Başarıyla Sepete Eklendi

The FST-12 is a tool to quickly split a 12-fiber ribbon into individual fibers or sub-groups with separation ratio from 1:11 to 6:6.

Ürün Başarıyla Sepete Eklendi

The FP-04T/05 provide these same performance levels for 8/12 fiber ribbon respectively. . The FPS04 and FPS08 series are specially designed for optical components, where small packaging is a priority. These micro sleeves provide the known reliability of Fujikura sleeves in the smallest possible lengths. This easy and cost effective method is a great alternative to recoating. The FPS01 and FPS04 series offer a wide range of options to accommodate various coating sizes, and are manufactured in a variety of lengths. This gives great flexibility in designing optical modules.

Ürün Başarıyla Sepete Eklendi

Nyfors Product. The AutoCleaver LDF™ (Fujikura edition) is a high precision fiber cleaver, designed for cleaving of large diameter fiber (LDF). It provides outstanding cleaving performance for large diameter fibers from 230 μm up to 1000 μm in diameter. The unique and patent pending cleaving process generates typical cleave angles of less than 0.5 degrees.

Ürün Başarıyla Sepete Eklendi

- TMM Telekom Makine Madencilik San. Ve Tic.Ltd.Şti, müşterilerinin çeşitli ihtiyaçları için uluslararası pazara hizmet veren uluslararası bir şirkettir.

- İletişim

- İletişim Formu

- Mail Gönder

- Bizi Takip Edin

_927163e5-d1b4-4309-8b9b-aac7fc87445d.png)

_5df15f60-a573-4570-87b1-b68674f7700c.png)

- Bizi Arayın

Sinyal ve Kontrol Kabloları

Sinyal ve Kontrol Kabloları

Çinko / Zn

Çinko / Zn

Kurşun / Pb

Kurşun / Pb

Specification Sheet

Specification Sheet